Design Guidance

Summary

Presented in the summary is the important information to the procedure, such as scope and responsibilities, but not procedure instructions. The worker has to review it and be acknowledged before entering the instruction.

(Design Guidance, Section 2.2.11)

Procedure specific information

While working through the task, procedure specific information such as title and current section should always be visible to worker.

(Design Guidance, Section 2.2.11)

Caution:

This caution message is placed immediately before applicable steps to inform workers of undesirable equipment results. The caution message is presented in conjunction with the step because it is relevant to the current conditions.

(Design Guidance, Sections 2.1.5 & 2.2.6)

Decision points: Fan set 2A or 2B

Conditional statements are presented as binary options to better support the worker’s decision process. The two options are clearly stated on the buttons, in this case which fan set is in service. Based on the option selected the system will guide the worker through the applicable path while none applicable steps automatically will be marked as such.

(Design Guidance, Section 2.5.1 & 2.1.6)

Context sensitive information

Step 6.1.1 is automatically populated with context-sensitive information based on the decision made in Step 6.1. If you scroll up, you will see that the previous step now clearly indicates the decision made.

(Design Guidance, Section 2.1.6)

Multiple action steps

The actions to be taken on the two switches are functionally related and aiming to achieve a single goal, i.e., to ensure they are in the AUTO position. These multiple actions are grouped together in one step, to ensure all actions in this step are executed before the worker may move to the next step. Bulleted steps are grouped together since they can be conducted in any order within the bulleted list.

(Design Guidance, Section 2.2.2)

Digital correct component verification

By utilizing the capabilities of digital technology the system supports the worker during the correct component verifications (CCV). Technologies such as RFID, optical character recognition, or barcodes can be used. The barcode is used to match the scanned component with the expected component. The system will alert the worker if the CCV failed, which will reduce risk for actions on incorrect components.

(Design Guidance, Section 2.6)

Context sensitive branching

Due to the input in Step 6.1.1 indicating one of the two fans is not yet in AUTO the worker was directed to this step. If both fans would have been in AUTO this particular step would have been automatically marked as not applicable and move the worker immediately to Step 6.2.

(Design Guidance, Section 2.1.6)

Context sensitive button

The button provides step instructions with context sensitive information “Mark as OFF” which serves a reminder to the worker of the actions to be taken and actions already taken.

(Design Guidance, Section 2.1.4)

Supporting documents

The supporting document can be easily accessed within a specific procedure step by providing the link of the document. The document is not displayed in the step to reduce risk of information overload and cluttering.

(Design Guidance, Section 2.2.7)

Timer

The system provides computerized support by preventing the worker from proceeding to the next step until prescribed time has lapsed.

(Design Guidance, Section 2.6)

Comment

The system improves the interaction between field worker, procedure and other involved operators by providing the commenting tool. The worker can leave a note or reminder regarding the specific step.

(Design Guidance, Section 2.7)

A summary of all notes as well as the option to make notes global to the procedure are found in the left side menu.

Previous steps

The worker can always scroll back to previous conducted steps to get an overview of actions taken and decisions made.

(Design Guidance, Section 2.2)

Active step

The active step is always clearly marked with a blue boarder in white background. All completed steps and future steps are greyed out. Action can only be taken on the active step, but workers can scroll through the list of steps. This computerized placekeeping prevents the worker from unintentionally conducting steps out of order or omitting a step within the procedure.

(Design Guidance, Section 2.2)

Navigation to active step

There are two options to easily navigate back to the active step. The arrow icon to the top right will take the worker to the active step. The right side menu also has an option to jump to the active step.

Automatically validate user input

The manual input can be automatically validated following a set of rules, such as type and value of the input. If the input is in violation of the predefined range or technical specification, the system will alert the worker, and then it gives the worker the option to revise the input.

(Design Guidance, Section 2.6.5 & 2.6.6)

Improve communication

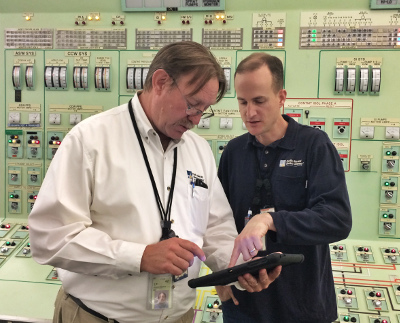

The system automated the communication between the field workers and control room operators as well as the work status information sharing between them. This will reduce the time currently needed to enable the worker to contact the control room.

(Design Guidance, Section 2.7.3)

Mark as complete

The system keeps workers engaged with the procedure by helping to track performance of the step. The worker is noticed when the current procedure is complete.

(Design Guidance, Section 2.2.5)

Summary

Presented in the summary is the important information to the procedure, such as scope and responsibilities, but not procedure instructions. The worker has to review it and be acknowledged before entering the instruction.

(Design Guidance, Section 2.2.11)

Procedure specific information

While working through the task, procedure specific information such as title and current section should always be visible to worker.

(Design Guidance, Section 2.2.11)

Note:

This note message is placed immediately before applicable steps to provide explanatory information to support a procedure step. This note is presented in conjunction with the step because it is relevant to the current conditions.

(Design Guidance, Sections 2.1.5 & 2.2.6)

Decision points: pump A or pump B

Conditional statements are presented as binary options to better support the worker’s decision process. The two options are clearly stated on the buttons. The system guides the worker through applicable steps based on the specific encountered conditions in the field.

(Design Guidance, Section 2.5.1 & 2.1.6)

Supporting documents

The supporting document can be easily accessed within a specific procedure step by providing the link of the document. The document is not displayed to reduce risk of information overload and cluttering.

(Design Guidance, Section 2.2.7)

Context sensitive information

The context-sensitive step instruction takes workers to the applicable steps based on the task information input by the worker in the previous step. The equipment is presented here regarding to the decision made.

(Design Guidance, Section 2.1.6)

Active step

The active step is always clearly marked with a blue boarder in white background. All completed steps and future steps are greyed out. Action can only be taken on the active step, but workers can scroll through the list of steps. This computerized placekeeping prevents the worker from unintentionally conducting steps out of order or omitting a step within the procedure.

(Design Guidance, Section 2.2)

Navigation to active step

There are two options to easily navigate back to the active step. The arrow icon to the top right will take the worker to the active step. The right side menu also has an option to jump to the active step.

Context sensitive button

The button provides step instructions with context sensitive information “Mark as Started” which serves a reminder to the worker of the actions to be taken and actions already taken.

(Design Guidance, Section 2.1.4)

Comment

The system improves the interaction between field worker, procedure and other involved operators by providing the commenting tool. The worker can leave note and reminder regarding this specific step. This has facilitated the computerized support on step-specific communication.

(Design Guidance, Section 2.7)

Automatically validate user input

The manual input can be automatically validated following a set of rules, such as type and value of the input. If the input is in violation of the predefined range or technical specification, the system will alert the worker, and then it gives the worker the option to revise the input.

(Design Guidance, Section 2.6.5 & 2.6.6)

Calculation based on manual input

The system uses the manual input to automatically calculate the level difference and flow rate. This step also gives the worker the option to review the calculation before moving on to the next step.

(Design Guidance, Section 2.6.1)

Multiple action steps

The actions on inputting these values are functionally related and aiming to achieve a single goal. These multiple actions are grouped together in one step, to ensure all actions in this step are executed before the worker may move to the next step.

(Design Guidance, Section 2.2.2)

Mark as complete

The system keeps workers engaged with the procedure by helping to track performance of the step. The worker is noticed when the current procedure is complete.

(Design Guidance, Section 2.2.5)

Computer-Based Procedures

Computer-Based Procedures